Cold Pilger Mill

Features

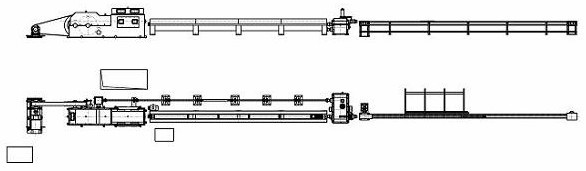

1. Our LG30-H cold pilger mill adopts pulley drive system and is suitable to process ferrous metal or nonferrous metal seamless tubes whose diameters range from 22mm to 48mm. Diameters of the pilgered tubes range from 19mm to 32mm.

2. This is an end-loading tube processing machine which can roll the tubes without moving the mandrel. Since the rolling speed and feed increment can be controlled automatically, this tube processing machine is easy to operate and has higher working efficiency. Our cold pilger mill has productivity 30%-50% higher than other common cold reduction mills made in China.

3. Our product has high rolling precision and can achieve tube cross section reduction rate up to 85% and wall thickness deviation rectification rate to 75%.

4. The finished tubes processed by our cold pilger mill are usually suitable for heat exchanger and automobiles.

Detailed Parameters

| Order | Item | Parameter | Unit | |

| 1 | Hollow tube | Outer diameter | Ф22~Ф48 | mm |

| Wall thickness | 2.0~4.5 | mm | ||

| Length | ≤7000 | mm | ||

| 2 | Finished tube | Outer diameter | Ф19~Ф32 | mm |

| Wall thickness | 1.2~3.0 | mm | ||

| 3 | Maximum elongation coefficient | Stainless steel≤2.5 | ||

| 4 | Stroke length of machine frame | 603 | mm | |

| 5 | Stroke number of machine frame | 65~110 | Time/min | |

| 6 | Rotation angle | 57 °~37 ° (Single rotation) | ||

| 7 | Feeding amount | 2.6 ~6.5 (Single feed) | mm | |

| 8 | Material loading mode | End loading | ||

| 9 | Diameter of the roll | Ф260 | mm | |

| 10 | Main motor | Model | Z4-200-31 | |

| Power | 55 | kW | ||

| Revolving speed | 1000 | rpm | ||

| Power supply | DC380V | |||

| 11 | Overall dimension | L×W×H | ≈30000 ×2100 ×1500 | mm |

English

English العربية

العربية Español

Español